tryg

New Member

The brakes are an important component of our vehicle that help control the vehicle and ensure the safety of our self as well as of the vehicle. The most commonly used type of brakes for the cars are the disc brakes.

The disc brake comprises of the rotor, which can be made up of materials like cast iron or ceramic. The rotor is connected either to the rotating wheel or the axle. When you apply the brakes the brake pads are pushed against the rotor by way of mechanical, hydraulic or electromagnetic force. The friction between the brake pads and the disc causes the stoppage of brake disc which in turn stops the rotation of the wheel of the vehicle. You can easily change the size of your front rotors and corresponding calipers, should you want an increase in braking performance.

One simple way to explain this is; My 2007 CJ ES has smaller rotor than a VRX of the same year, if comparing their diameters. Each mount the same but have different calipers to ensure the stretch from centre, accommodating their specific rotor. I could (and want) to buy some VRX calipers and rotors to effect this change. Ralliarts again have larger, then Evo larger again. This can be applied to your vehicle. Aftermarket companies make rotors from 12", way up to 18" rotors and single pot to 8-piston calipers.. these really increase braking performance, but at a price.

The brake rotors are subjected to extremely high friction that generates lot of heat within it. The material and the construction of the rotors should be such that they should be able to sustain these high pressures and they should also be able to release the large amounts of heat generated within them.

Considering the above factors, three types of constructions have been successfully adopted for the rotors. These are cross drilled rotors, slotted rotors and cross drilled and slotted rotors.

Here are their peculiar features:

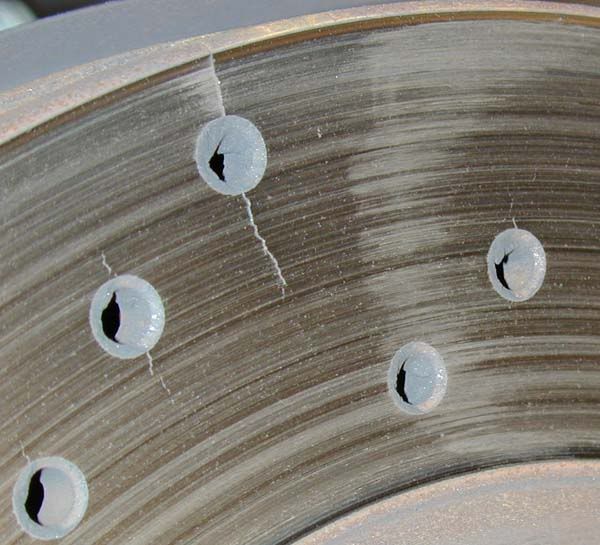

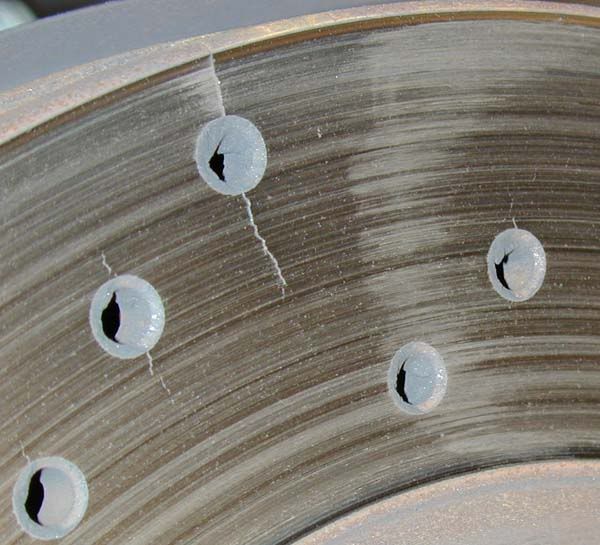

Cross drilled rotors - Over the surface of brake discs (or the rotor), a number of holes are drilled from one side to the other side. When brake pads come in contact with the disc lots of heat and gas is generated, the cross drills provide an easy escape for them, thus maintaining the performance of the brakes of the vehicle. Look at most motorcycle rotors, they are drilled.

One drawback can be cracking around the drilled holes. Some have countersunk and tempered chamfers to prevent this type of damage.

Slotted rotors - To remove the heat generated with the rotors, they may also be slotted. The slots are shallow channels machined on the surface of the disc. The slots can be of various depth and width and can be machined in various angles.

Cross drilled and slotted rotors - To take both benefits of crossed holes and slots has become extremely popular. In these rotors the heat can escape either from the holes or the slots. In rainy season or on wet roads, the holes or slots prevent formation of water film between the rotor and the brake pads, thus avoiding the chance of corrosion and generation of gas due to heat.

Since the heat and gases generated in cases of the drilled and slotted rotors is released quickly, the brake works with maximum efficiency preventing skidding and locking up. Even their response is very fast stopping your vehicle quickly in case of routine and emergency application of the brakes.

Types of friction material

Ceramic Brake Pads

Ceramic brake pads, are composed of a mix between ceramic compounds and tiny copper fibers. The ceramic compound reduces brake dust and dissipates heat, while the copper fibers add strength and durability. This results in a faster reaction time and a smoother, quieter braking cycle, while keeping your wheels free of unsightly brake dust. The benefits of ceramic brake pads are best experienced in a performance vehicle such as sports car, mainly because they perform better than semi metallic brake pads when under heavy stress.

The biggest drawback of ceramic vs. semi metallic brake pads is their high price. At nearly twice the price of semi metallic pads, it’s hard for most drivers to see the incentive. For performance driving, the additional cost can easily be justified by their superior performance at high speeds. However, for everyday vehicles the cost v's benefit may outweigh their need.

Semi Metallic Brake Pads

Semi metallic brake pads, sometimes called metallic brake pads, are made from a combination of brass, copper and steel fibers bonded together by a strong resin. Though the exact mixture varies depending on the manufacturer, the formula is usually chosen to increase either performance or longevity. These different formulas are often offered as different brake pad grades, with the premium and performance grades boasting superior stopping power over the standard and economy grades, which generally provide a longer pad life.

The biggest drawback of semi metallic brake pads is a shorter life expectancy vs. ceramic brake pads. However, at nearly half the price, the cost to longevity ratio clearly favors semi metallic brake pads. For most vehicles, semi metallic brake pads are simply the most economic choice. Semi metallic brake pads are overwhelmingly the most common type of brake pads found on cars today.

We wont go into carbon brakes, as they are simply worth more than the cars we drive!!

The disc brake comprises of the rotor, which can be made up of materials like cast iron or ceramic. The rotor is connected either to the rotating wheel or the axle. When you apply the brakes the brake pads are pushed against the rotor by way of mechanical, hydraulic or electromagnetic force. The friction between the brake pads and the disc causes the stoppage of brake disc which in turn stops the rotation of the wheel of the vehicle. You can easily change the size of your front rotors and corresponding calipers, should you want an increase in braking performance.

One simple way to explain this is; My 2007 CJ ES has smaller rotor than a VRX of the same year, if comparing their diameters. Each mount the same but have different calipers to ensure the stretch from centre, accommodating their specific rotor. I could (and want) to buy some VRX calipers and rotors to effect this change. Ralliarts again have larger, then Evo larger again. This can be applied to your vehicle. Aftermarket companies make rotors from 12", way up to 18" rotors and single pot to 8-piston calipers.. these really increase braking performance, but at a price.

The brake rotors are subjected to extremely high friction that generates lot of heat within it. The material and the construction of the rotors should be such that they should be able to sustain these high pressures and they should also be able to release the large amounts of heat generated within them.

Considering the above factors, three types of constructions have been successfully adopted for the rotors. These are cross drilled rotors, slotted rotors and cross drilled and slotted rotors.

Here are their peculiar features:

Cross drilled rotors - Over the surface of brake discs (or the rotor), a number of holes are drilled from one side to the other side. When brake pads come in contact with the disc lots of heat and gas is generated, the cross drills provide an easy escape for them, thus maintaining the performance of the brakes of the vehicle. Look at most motorcycle rotors, they are drilled.

One drawback can be cracking around the drilled holes. Some have countersunk and tempered chamfers to prevent this type of damage.

Slotted rotors - To remove the heat generated with the rotors, they may also be slotted. The slots are shallow channels machined on the surface of the disc. The slots can be of various depth and width and can be machined in various angles.

Cross drilled and slotted rotors - To take both benefits of crossed holes and slots has become extremely popular. In these rotors the heat can escape either from the holes or the slots. In rainy season or on wet roads, the holes or slots prevent formation of water film between the rotor and the brake pads, thus avoiding the chance of corrosion and generation of gas due to heat.

Since the heat and gases generated in cases of the drilled and slotted rotors is released quickly, the brake works with maximum efficiency preventing skidding and locking up. Even their response is very fast stopping your vehicle quickly in case of routine and emergency application of the brakes.

Types of friction material

Ceramic Brake Pads

Ceramic brake pads, are composed of a mix between ceramic compounds and tiny copper fibers. The ceramic compound reduces brake dust and dissipates heat, while the copper fibers add strength and durability. This results in a faster reaction time and a smoother, quieter braking cycle, while keeping your wheels free of unsightly brake dust. The benefits of ceramic brake pads are best experienced in a performance vehicle such as sports car, mainly because they perform better than semi metallic brake pads when under heavy stress.

The biggest drawback of ceramic vs. semi metallic brake pads is their high price. At nearly twice the price of semi metallic pads, it’s hard for most drivers to see the incentive. For performance driving, the additional cost can easily be justified by their superior performance at high speeds. However, for everyday vehicles the cost v's benefit may outweigh their need.

Semi Metallic Brake Pads

Semi metallic brake pads, sometimes called metallic brake pads, are made from a combination of brass, copper and steel fibers bonded together by a strong resin. Though the exact mixture varies depending on the manufacturer, the formula is usually chosen to increase either performance or longevity. These different formulas are often offered as different brake pad grades, with the premium and performance grades boasting superior stopping power over the standard and economy grades, which generally provide a longer pad life.

The biggest drawback of semi metallic brake pads is a shorter life expectancy vs. ceramic brake pads. However, at nearly half the price, the cost to longevity ratio clearly favors semi metallic brake pads. For most vehicles, semi metallic brake pads are simply the most economic choice. Semi metallic brake pads are overwhelmingly the most common type of brake pads found on cars today.

We wont go into carbon brakes, as they are simply worth more than the cars we drive!!